Polyurethane foam is a material widely used in construction, transportation, furniture, and other fields. Its excellent thermal insulation performance, durability, and lightweight characteristics make it the material of choice in many fields. However, with the increasing demand for product safety and environmental protection, the quality and safety of polyurethane foam products are also drawing increasing attention. Therefore, it is important to develop relevant testing standards to ensure product quality and protect consumers’ rights and interests. This paper will introduce the main applications of polyurethane foam products and their important testing standards, to help readers better understand the applications and quality assurance of polyurethane foam products.

What are Polyurethane Foam Products?

Polyurethane foam is a kind of polymer material made by polymer chemical reaction, which has the characteristics of lightweight, heat insulation, and fireproof, and is widely used in construction, automobile, home appliance, aerospace, and other fields.

The history of polyurethane foams dates back to the 1940s when the German chemist Otto Bayer discovered that polyurethane could be synthesized by polymer chemistry. In the following decades, polyurethane foams have been extensively researched and developed, and their applications have expanded. The development of polyurethane foams has gone through the following main stages:

- Initial stage (the 1940s-1960s): mainly used in the fields of aerospace, building insulation, and so on.

- Development stage (the 1970s-1980s): As the performance of polyurethane foam materials continued to improve, their application fields gradually expanded, including automobile manufacturing, ships, home appliances, and other fields.

- Mature stage (1990s-present): The application fields of polyurethane foam materials are more extensive, such as manufacturing refrigerators, air conditioners, insulation materials, and so on.

At present, the application prospect of polyurethane foam materials in the fields of construction, automobile, home appliance, aerospace, and so on. is very broad. For example, in the field of construction, polyurethane foam can be used for wall insulation, roof insulation, and ground insulation. In the field of automobiles, polyurethane foam can be used to manufacture seats, steering wheels, doors, roofs, and other parts; in the field of home appliances, polyurethane foam can be used to manufacture refrigerators, air conditioners, water heaters, and other products.

Types and Classification Criteria

Polyurethane foam products can be classified according to several aspects such as chemical structure, physical properties, and application areas. The following are the types of polyurethane foam products and their characteristics classified according to different classification criteria.

Classification according to the chemical structure

- Polyester polyurethane foam: Prepared from polyol and polyacid ester, it has good temperature resistance and strength, and is suitable for manufacturing products with high strength, high temperature, or corrosion resistance.

- Polyether polyurethane foam: Prepared from polyol and polyether, it has good flexibility and toughness, and is suitable for manufacturing products that require soft performance.

- Hybrid polyurethane foam: It is a more comprehensive polyurethane foam made by mixing polyester-type and polyether-type raw materials, which combines the advantages of both types.

Classification according to physical properties

- Open-type polyurethane foam: The pores are of different sizes, usually used in the fields of sound absorption, sound insulation, and shockproofing.

- Closed-type polyurethane foam: uniform pore size, good airtightness, used in the fields of heat insulation, thermal insulation, and so on.

Classification according to application areas

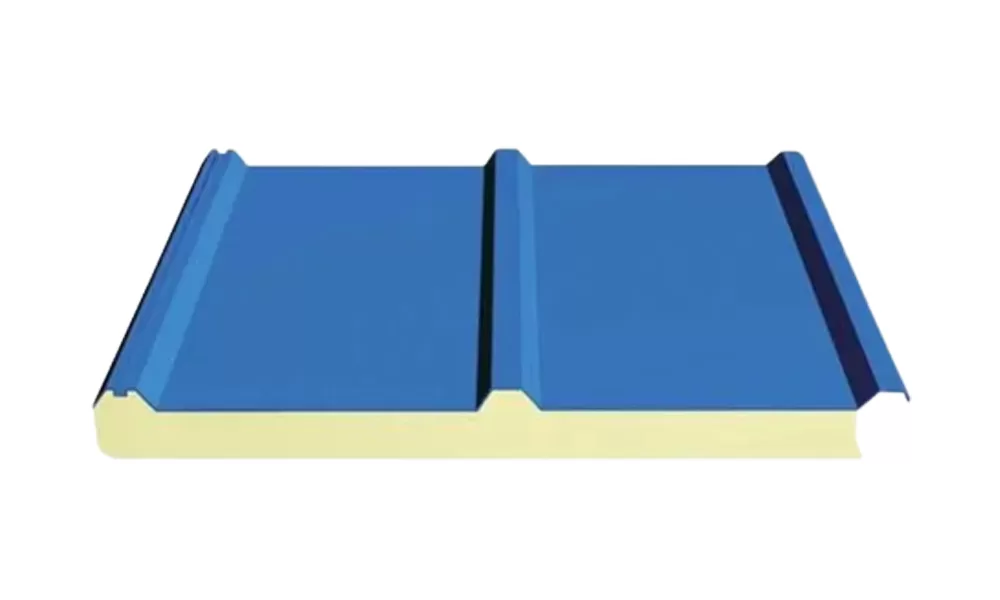

- Building insulation board: Used for building heat insulation, divided into two types open and closed type.

- Automobile seats: Used in the manufacture of automobile interiors, with better softness and comfort.

- Home appliance insulation materials: Used in the manufacture of refrigerators, air conditioners, water heaters, and other home appliances, with better heat insulation performance.

- Aerospace materials: Used in the manufacture of aerospace devices, with lightweight, high strength, high-temperature resistance, and other characteristics.

- Medical materials: Used in the manufacture of medical devices such as prostheses and support rods, with good biocompatibility.

Classification according to density

Polyurethane foam can also be classified according to density and is usually divided into three types: high-density, medium-density, and low-density. The density of high-density polyurethane foam is greater than 100kg/m³, the density of medium-density polyurethane foam is between 50-100kg/m³, and the density of low-density polyurethane foam is less than 50kg/m³. Polyurethane foam materials with different densities have different physical properties and application areas.

Classification according to hardness

Polyurethane foam can also be classified according to hardness and is usually divided into three types: rigid, semi-rigid, and flexible. Rigid polyurethane foam has higher hardness and is suitable for manufacturing high-strength products; semi-rigid polyurethane foam has better flexibility and toughness and is suitable for manufacturing products that require flexibility and strength; soft polyurethane foam has better flexibility and shock-absorbing properties and is suitable for manufacturing products that require shock-absorbing properties.

In short, polyurethane foam products can be divided according to many different classification criteria, and each type of polyurethane foam material has its own unique characteristics and application areas, which need to be selected according to specific application needs.

Applications

Polyurethane foam products are a material with excellent performance, with good heat insulation, heat preservation, sound absorption, waterproofing, fireproofing, pressure resistance, and other properties, so it has a wide range of applications in many fields, some of the main applications areas include:

- Construction field: It can be made into heat insulation materials and used in walls, roofs, floors, and other parts of buildings, which can effectively improve the energy efficiency of buildings, save energy, and reduce operating costs.

- Transportation field: It can be made into lightweight materials and used in heat insulation, shock absorption, noise reduction, and other parts of cars, airplanes, trains, and other means of transportation, which can improve the performance and comfort of vehicles.

- Furniture field: It can be made into upholstery, seats, and other parts with good elasticity and comfort, and can also be made into insulation materials for refrigerators, freezers, and other electrical products.

- Electronic field: can be made into packaging materials for electronic products, with shockproof, anti-static, and other properties, which can protect the safety of electronic equipment.

- Medical field: It can be made into isolation and shock absorption parts of medical equipment, and can also be made into materials for medical devices such as extracorporeal circulation, which have good biocompatibility and mechanical properties.

Features and Performance

Polyurethane foam products have a variety of excellent properties and characteristics, mainly including the following:

- Heat insulation performance: With excellent heat insulation performance, it can effectively reduce the transmission and loss of energy, and is suitable for construction, refrigeration equipment, HVAC, and other fields.

- Sound absorption and noise reduction performance: With good sound absorption and noise reduction performance, it can reduce the transmission and reflection of noise, improve the comfort and quietness of the environment, and is suitable for construction, transportation, furniture, and other fields.

- Seismic performance: It has good seismic performance, which can effectively reduce vibration and loss during an earthquake, and is suitable for construction, bridges, tunnels, and other fields.

- Fireproof performance: With good fireproof performance, can reduce the occurrence and spread of fire, suitable for construction, transportation, and other fields.

- Compressive performance: It has good compressive performance and can withstand large pressure without deformation and damage, which is suitable for construction, transportation, furniture, and other fields.

- Chemical stability: It has good chemical stability and is not easy to be eroded and affected by chemical substances and water, so it is suitable for occasions that need long-term use.

- Processing performance: It has good processing performance and can be processed and manufactured by spraying, injection, and casting so it can meet the needs of different fields and products. At the same time, polyurethane foam products can be compounded with other materials to improve their performance and application scope.

These properties make polyurethane foam products widely used in many fields such as construction, transportation, electronics, medicine, and aerospace.

Production Process

The production process of polyurethane foam products generally includes the preparation of raw materials, foaming, curing, and other aspects.

- Preparation of raw materials: Raw materials generally include polyacetal, isocyanate, catalyst, stabilizer, blowing agent, and so on. Before production, these raw materials need to be formulated in a certain proportion to ensure the quality and performance of the product.

- Foaming: After the raw materials are prepared, they will be added to the foaming equipment for foaming. The foaming equipment generally adopts different equipment such as a spraying machine, injection machine, and casting machine. Different foaming methods are selected according to the different requirements of the products. In the process of foaming, the blowing agent will decompose and produce gas, which makes the raw material expand and foam to form polyurethane foam.

- Curing: The foamed polyurethane foam needs to be cured to make it have a stable shape and performance. The curing process requires attention to factors such as ambient temperature and humidity, as well as curing time and conditions.

- Processing and molding: After curing, the polyurethane foam can be processed and molded. The processing method generally adopts cutting, trimming, and grinding to meet the requirements of different products. Forming can be done by pressure forming and mold forming. to make polyurethane foam products of different shapes and sizes.

- Quality control process: In the production process, strict quality control is needed for raw materials, production equipment, and finished products to ensure that the quality and performance of the products meet the requirements. The quality control process includes inspection of raw materials, monitoring and maintenance of production equipment, sampling, and inspection of finished products. Through strict quality control, the stability and reliability of the products are ensured.

- Environmental protection process: The production process needs to pay attention to environmental protection issues to avoid pollution and impact on the environment. The environmental protection process includes waste disposal, wastewater treatment, waste gas treatment, and other links to reduce the emission of waste and the negative impact on the environment through the use of environmental protection equipment and measures.

It should be noted that the quality and proportion of raw materials, parameters and conditions of foaming equipment, curing conditions and time, and other factors need to be strictly controlled in the production process to ensure the stability and quality of the products. At the same time, the production process needs to pay attention to environmental protection and safety and other aspects to avoid damage to the environment and staff.

Environmental Performance and Standards

Polyurethane foam material, as a new type of building material, has excellent performance, but the production process of polyurethane foam products also generates certain environmental pollution. Therefore, to protect the environment and human health, the environmental performance and standards of polyurethane foam products are crucial.

Environmental indicators

The main environmental indicators of polyurethane foam products include VOC emission, formaldehyde emission, sustainability, and life cycle analysis. VOC refers to volatile organic compounds, which are one of the main components of air pollution, while formaldehyde is a harmful substance that may cause harm to human health. Sustainability refers to the impact on the environment and resource utilization during the production and use of the product, while life cycle analysis refers to the impact on the environment during the whole process from raw material procurement, production, transportation, and use to waste disposal of the product.

Environmental standards

The main international environmental standards for polyurethane foam products are as follows:

- EU REACH regulation: REACH is an EU regulation on chemicals management, which stipulates that all chemicals sold in the EU must be registered, evaluated, and authorized within the scope of REACH regulations. Polyurethane foam products are also included in the management scope of REACH and need to meet the relevant environmental indicators and standards.

- US LEED certification: LEED certification is a certification issued by the US Green Building Council to evaluate the environmental performance and sustainability of buildings and building materials, which includes the use of polyurethane foam products.

- China GB/T standard: The National Standardization Committee of China has issued a national standard for polyurethane foam products, which includes environmental indicators and standards for polyurethane foam products.

- ISO standards: The International Organization for Standardization has also issued several environmental standards related to polyurethane foam products, such as the ISO 14001 environmental management system standard.

These standards all put forward strict requirements for the environmental performance of polyurethane foam products, and promote the continuous improvement of the environmental technology of polyurethane foam products, gradually achieving better protection of the environment.

Safety Performance and Standards

This is because polyurethane foam products can produce harmful chemicals and safety hazards during the manufacturing and use process. Therefore their safety performance and standards are an important issue. The safety performance and standards of polyurethane foam products are described in detail below.

Safety indicators

- Thermal conductivity: The smaller the thermal conductivity of polyurethane foam, the better the insulation performance, which can reduce the waste of energy and environmental pollution.

- Combustion performance: The combustion performance of polyurethane foam refers to its indicators such as burning speed and heat release in a fire. For applications in construction and other fields, polyurethane foam must meet the requirements of fire rating to ensure the safety performance of the building.

- Chemical stability: The chemical stability of polyurethane foam refers to its stability under exposure to air, water, light, and other factors. Some chemicals can corrode and degrade polyurethane foam, so the chemical stability of polyurethane foam must be ensured.

Safety Standards

- U.S. Standard: The Federal Aviation Administration (FAA) promulgated the “Specification for the Use of Polyurethane Foam Materials”, which specifies the safety requirements for polyurethane foam products in the aviation industry.

- European Standard: The European Committee for Standardization (CEN) promulgated the Specification for Polyurethane Foam Products (EN 14315-1:2004), which stipulates the requirements for physical properties, combustion properties, and chemical stability of polyurethane foam products.

- Chinese Standard: The Chinese National Standardization Committee promulgated the standard “Polyurethane Foam and Products” (GB/T 6343-2009), which stipulates the requirements of material and physical properties, thermal stability, flame retardant properties, expansion properties, and combustion properties. of polyurethane foam products.

These standards cover the following main areas:

- Physical properties: Including the density, thermal conductivity, tensile strength, compressive strength, bending strength, and other physical property indexes of polyurethane foam products.

- Chemical stability: Including the chemical properties, heat resistance, weather resistance, and other requirements of polyurethane foam products.

- Combustion performance: Including the combustion performance indexes such as flame retardant performance, heat release, and smoke density of polyurethane foam products.

- Environmental friendliness: Including the requirements of environmental properties such as halogen-free, lead-free, and mercury-free polyurethane foam products.

In addition, polyurethane foam products need to meet the requirements of relevant laws and regulations in various countries, such as the European Union Regulation on Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH), the U.S. Toxic Substances Control Act (TSCA), China Chemical Management Regulations, and so on. These regulations mainly require that polyurethane foam products do not produce harmful chemicals during the manufacturing and use process to ensure human health and environmental safety.

In general, the safety performance and standard of polyurethane foam products is a comprehensive issue, which needs to be considered from many aspects, such as physical properties, chemical stability, combustion properties, and environmental protection, to ensure its safety and environmental protection in the process of manufacturing and use.

Physical Properties and Testing Standards

Physical Properties

- Density: The density of foam material refers to the mass per unit volume, which is generally expressed by kg/m³ or lb/ft³. Usually, the density of polyurethane foam ranges from 30-200kg/m³.

- Compression strength: The compression strength of foam material refers to the maximum compression load per unit area, which is usually expressed in kPa or psi. The compression strength of polyurethane foam is generally between 100-300kPa.

- Thermal conductivity: The thermal conductivity of foam material refers to the amount of heat transferred per unit thickness of the material per unit time, usually expressed using W/(m-K) or Btu/(hr-ft-°F). The thermal conductivity of polyurethane foam is generally between 0.018-0.022W/(m-K).

- Water absorption rate: The water absorption rate of foam material is the ratio of the weight of water absorbed by the material to the initial weight of the material in a certain time, generally using % to express. The water absorption rate of polyurethane foam is generally between 2-5%.

Testing Standards

- ASTM standards: ASTM (American Society for Testing and Materials) has developed several standards related to foam materials, including standards for testing the physical properties of polyurethane foam products, such as ASTM D1622-08 (Compression performance test of polyurethane foam sheets and blocks), ASTM D1621-10 (compression strength test of polyurethane foam sheets and blocks), ASTM C518-17 (thermal conductivity test), and so on.

- European EN standards: The European Organization for Standardization (CEN) has also standardized the physical properties of polyurethane foam products. Among them, EN 12086-1:2013 (Foam thermal insulation materials. Polyurethane foam. Normative requirements) and EN 13165:2012 (Thermal insulating materials for construction. Polyurethane foam products. Specification requirements) are the standards related to polyurethane foam.

- Chinese GB standards: Chinese national standards also regulate the physical properties of polyurethane foam products, including GB/T 6343-2009 (Test methods for physical properties of foam polyurethane plastics and products), GB/T 1636-2010 (Test methods for physical properties of rigid foam) and GB/T 17794-2008 (Test methods for compression properties of polyurethane foam sheets and blocks). Compression properties test method) and other standards.

- International ISO standards: The International Organization for Standardization (ISO) has also formulated several standards related to foam materials, including standards for testing the physical properties of polyurethane foam products, such as ISO 845-2006 (test method for compression properties of foam. Test method for compression properties of rigid foam), ISO 1923-1:2017 (Foam. Test methods for polyurethane foam), and so on.

In general, the testing standards for polyurethane foam products are similar to those for other foam materials and usually include tests for density, compressive strength, thermal conductivity, water absorption, and other indicators. These standards play an important role in the quality control and standardized production of the products and also help to guarantee the effectiveness and safety of the use of the products.

Chemical Properties and Testing Standards

Chemical Properties

- Composition: Polyurethane foam products are usually made of a mixture of isocyanate, polyether polyol, catalyst, blowing agent, additives, and other components. Among them, the type and proportion of isocyanate and polyether polyol determine the performance and usage of the foam material.

- Reaction nature: Polyurethane foam products are produced by the polymerization reaction of isocyanate and polyether polyol, whose reaction rate, hardening time, reaction heat, and other properties affect the foaming performance, density, and physical properties of the products.

- Stability: The stability of polyurethane foam products includes their water resistance, oxidation resistance, UV radiation resistance, and so on. The goodness of these properties determines the service life and durability of the products.

Testing Standards

- Component analysis: The content and types of various components in foam products are tested by using analytical methods such as chromatography and infrared spectroscopy.

- Reaction performance testing: Including tests on polymerization reaction kinetics, hardening time, reaction heat, polymerization degree, and so on.

- Stability test: Including water resistance, oxidation resistance, UV radiation resistance, and other aspects of the test.

- Combustion performance test: Including the test of combustion grade, smoke density, toxic gas emission, and so on.

Common international standards for chemical performance testing include ASTM C1639-16 (Standard test method for determining alcohol content in polyurethane foam), ASTM D6342-12 (Test method for isocyanate content in polyurethane foam), and ISO 4892-3:2016 (Determination of lightfastness of plastics – Part 3: Laboratory test method for exposure to artificial xenon arc light sources).

Quality Control and Testing Technology

Quality control is an important part of the production process to ensure that the product meets quality requirements. The following are common quality control methods for polyurethane foam products:

Control Method

- Raw material control: The quality of raw materials needs to be controlled during the production process to ensure that the raw materials meet the product requirements. Comprehensive testing and evaluation of raw materials, including testing their composition, purity, moisture content, and so on.

- Production process control: Through strict production process control, including equipment control, control of reaction temperature, time, pressure, and other parameters, to ensure the quality stability and consistency of the products.

- Product testing: Comprehensive inspection and testing of products, including appearance inspection, physical property testing, and chemical property testing to ensure that the products meet the relevant standards and requirements.

Testing Technology

- Density measurement: Measure the density of polyurethane foam products by using a densitometer and other equipment to detect whether the porosity and density of the foam material meet the requirements.

- Tensile strength measurement: The tensile strength of polyurethane foam products is measured by equipment such as a tensile tester to detect whether its mechanical properties meet the requirements.

- Compression strength measurement: The compression strength of polyurethane foam products is measured by a compression tester and other equipment to test whether its compression resistance meets the requirements.

- Thermal stability measurement: The thermal stability of polyurethane foam products is measured by a thermogravimetric analyzer and other equipment to test whether the heat resistance performance meets the requirements.

Common international technical standards for testing polyurethane foam products include ASTM D1622-17 (test method for density and porosity of polyurethane foam materials), ASTM D3574-17 (test method for flexible foam polymeric materials), ASTM D1621-17 (test method for compression properties), and so on.

Conclusion

Polyurethane foam’s adaptability and performance make it indispensable in modern industries. By understanding its properties, applications, and the standards governing its use, one can harness its full potential responsibly. As we continue to innovate, it’s crucial to ensure that such materials are produced and utilized sustainably, keeping both environmental and safety concerns at the forefront.