Mold release agents have an important impact on polyurethane(PU) foam products, which can play a role in reducing friction and preventing adhesion during the manufacturing process, thus ensuring a smooth surface and stable quality of the products. In addition, the correct selection and use of mold release agents can also improve production efficiency, reduce production costs and extend mold life. In this paper, we will discuss the influence of mold release agents on polyurethane foam products and introduce how to correctly select and use mold release agents to achieve the best production results.

What is the Mold Release Agent?

Mold release agents are chemical coatings commonly used in manufacturing processes whose primary function is to facilitate the separation between the mold and the model. They are usually applied to the surface of the mold to ensure that the finished product can be separated from the mold smoothly and to avoid damage or distortion due to adhesion. Mold release agents are usually used in liquid, paste or spray form and have characteristics such as anti-adhesive, anti-corrosive, and lubricating properties.

The main components of mold release agents include solvents, lubricants, fillers, thickeners, and so on. Different manufacturing processes and materials require the use of different types of release agents. For example, in the manufacture of plastic products, the common release agents are mainly silicone oil and liquid paraffin; in the manufacture of rubber products, a mixture of release agent and the vulcanizing agent is usually used; and in the casting of metals, a release agent that is stable at high temperatures is required.

The use of mold-release agents can bring multiple benefits. First, it extends the life of the mold because the mold is no longer damaged by frequent friction and adhesion. Secondly, a mold release agent can reduce production costs because it reduces the rate of damage to the finished product and increases production efficiency, reducing production time and labor costs. Finally, the use of mold release agents ensures a smooth, flawless surface on the finished product, thereby improving product quality and customer satisfaction.

It is important to note that the instructions and safety procedures need to be strictly followed when using mold release agents to avoid accidents.

What is the Process of Making Polyurethane Foam Products?

Due to space limitations, the following steps are briefly summarized and described in more detail in my article Basic Steps in the Production of Polyurethane Products.

- Raw material preparation: Polyether polyol, polyisocyanate, catalyst, stabilizer, blowing agent, and other raw materials are needed for the production of polyurethane foam. These raw materials need to be mixed in a certain proportion and environmental conditions such as temperature and humidity is strictly controlled.

- Foaming: The mixed raw materials are injected into the foaming machine, and under the action of the machine, the foaming agent in the raw materials starts to fully expand and generate a large number of bubbles to form foam.

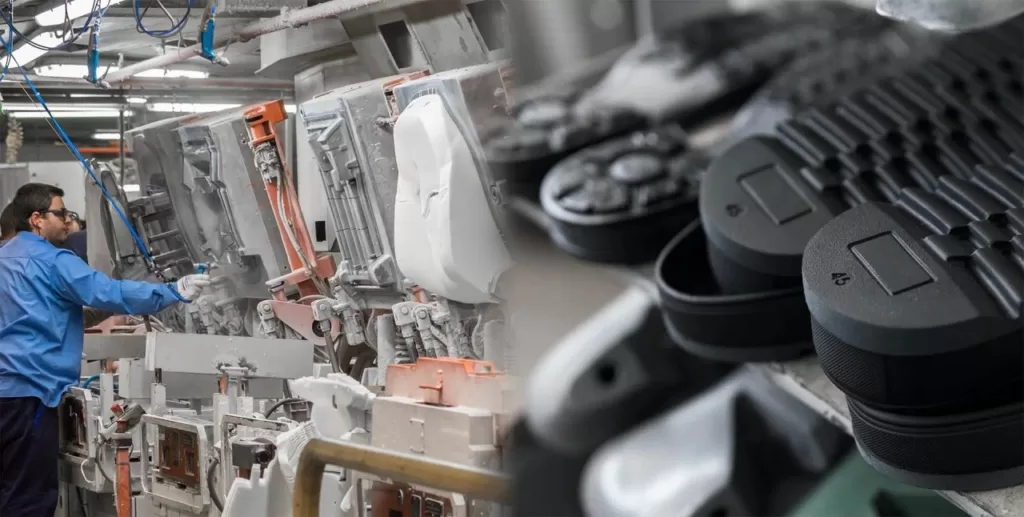

- Forming: The foam is injected into the mold and shaped within a certain period of time. Polyurethane foam can be used to produce various shapes of products, such as seats, sound insulation panels, insulation materials, and so on.

- Curing: After molding, polyurethane foam needs to be cured to improve its strength and stability. The curing process requires control of conditions such as temperature and humidity, and specific curing times depending on the needs of different products.

- Painting and processing: After molding and curing, polyurethane foam products can be painted and processed to change their properties such as surface color and shape.

These are the basic steps of the production process of polyurethane foam products. The specific production process may vary depending on factors such as product type and application.

What is the Role of Release Agents in the Production of PU Foam Products?

Specifically, the role of mold release agents includes the following:

- Reduce the friction on the surface of the mold: The production of polyurethane foam requires the injection of well-mixed raw materials into the mold for molding. If the friction on the surface of the mold is too large, it will cause the raw material cannot fully fill the inside of the mold when injected, thus affecting the quality and surface smoothness of the product. The use of a mold release agent can effectively reduce the friction on the surface of the mold so that the raw material can better fill the inside of the mold.

- Prevent the products from sticking to the mold surface: In the process of making polyurethane foam, the molded products need to be taken out from the mold. If the product adheres too tightly to the mold surface, it will cause damage to the product or cannot be taken out. A mold release agent can prevent the product from adhering too tightly to the mold surface, thus facilitating the removal of the product.

- Improve the smoothness of the product surface: The use of mold release agents can form a thin protective film when molding polyurethane foam products, which can make the product surface smoother.

- Extend the service life of the mold: The use of a mold release agent can reduce the wear and tear of the mold, reduce the corrosion and oxidation of the mold surface, and thus can extend the service life of the mold.

Mold release agents play a vital role in the production of polyurethane foam products, improving product quality and productivity, reducing production costs, protecting the mold, and extending its life.

What are the Types of Mold Release Agents?

Classification according to composition

- Silicone oil type mold release agent: The main component is polydimethylsiloxane (PDMS), suitable for the release of various plastic products, and rubber products, and has a good effect on mold release.

- Lubricating release agent: The main component is paraffin wax or waxen, suitable for the release of large molding parts or high-strength metal castings, with a good lubrication effect.

- Synthetic mold release agent: The main components are chemically synthesized polymer compounds, suitable for the release of various metals, ceramics, and other materials, with good anti-corrosion properties.

Classification according to usage

- Metal release agent: applicable to the release of metal materials, such as aluminum alloy, and magnesium alloy.

- Rubber release agent: applicable to the release of various rubber products, such as rubber seals, and rubber pipe fittings.

- Plastic release agent: applicable to the release of various plastic products, such as injection parts, and blow molding parts.

Classification according to morphology

- Liquid mold releasing agent: such as liquid silicone oil type mold releasing agent, liquid synthetic mold releasing agent.

- Solid mold releasing agent: such as wax type mold releasing agent, metal mold release paste.

There is a wide range of mold release agents, and different types of release agents are suitable for different materials and release requirements.

How do Different Types of Release Agents Affect PU Foam Products Differently?

Silicone oil-based mold release agents generally have excellent release effects and can leave polyurethane foam products with smooth, flawless surfaces. However, silicone oil-based mold release agents may leave a silicone oil film on the surface of polyurethane foam products, which may affect the adhesion of the coating and adhesive.

Lubricating release agents, on the other hand, provide better lubrication, which facilitates the molding and release of polyurethane foam products. However, if used in excess or selected improperly, they may leave a residue on the surface of the polyurethane foam product and reduce the surface quality.

Synthetic mold release agents provide good mold release and corrosion resistance, but some ingredients may negatively affect the surface quality of polyurethane foam products.

In conclusion, choosing the appropriate release agent can improve the production efficiency and quality of polyurethane foam products, but it needs to be selected and used according to the specific situation in order to avoid a negative impact on the products.

When Do I Need to Use a Mold Release Agent?

The main situations that require the use of release agents include the following:

- When polyurethane foam products need to be released from the mold, the use of a mold release agent can reduce the friction and make the release easier.

- When using complex molds or making larger polyurethane foam products, the use of mold release agents can prevent the products from sticking to the molds and protect the life of the molds.

- For polyurethane foam products that require a smooth surface, the use of mold release agents can reduce surface defects and improve the surface quality of the product.

- In the production process, polyurethane foam products may adhere to the mold or other materials, the use of mold release agents can reduce the adhesion phenomenon and improve production efficiency.

In conclusion, the use of mold release agents can improve production efficiency, protect the mold and improve product quality, which has an important role in the production of polyurethane foam products.

What are the Requirements for the Amount and Method of Release Agent Application?

Control of the amount used

When using the release agent, it is necessary to control the amount used and avoid using too much. Excessive use will cause the release agent to be left on the surface of polyurethane foam products, which will affect the adhesion and surface quality of the products.

Uniform coating

The release agent needs to be evenly coated on the surface of the mold to ensure that every part of the polyurethane foam product can be lubricated and protected by the release agent.

Time control

The time of using the release agent needs to be controlled to avoid releasing the mold too early before the polyurethane foam product hardens or too late after the polyurethane foam product hardens.

Choose a suitable release agent

According to the molding conditions and requirements of polyurethane foam products, choose a suitable release agent to ensure that the release agent is compatible with the product surface and will not affect the product quality.

Operation safety

When using the release agent, you need to pay attention to operation safety, avoid contact with the release agent with your skin and eyes, wear appropriate protective equipment and keep good ventilation.

Does the Use of Release Agents Affect the Quality of PU Foam Products?

The use of release agents can have an impact on the quality of polyurethane foam products, but the exact impact depends on the type of release agent, the method of application, and the amount used.

Using the right release agent, applying it evenly, and controlling the amount used will not have a significant impact on the quality of polyurethane foam products. On the contrary, the use of release agents can contribute positively to the quality of the product by reducing friction, preventing product adhesion, protecting the mold, and improving productivity.

However, if the release agent is used in excess, unevenly coated, or used for an inappropriate period of time, it can lead to the residue of the release agent on the surface of polyurethane foam products and affect the adhesion and surface quality of the products. In addition, some unsuitable release agents may react with the materials of polyurethane foam products, leading to quality problems.

Therefore, it is necessary to choose suitable release agents, use them correctly, and control the amount used, and proper testing and quality control are needed to ensure the quality of polyurethane foam products.

How to Properly Handle Mold Release Agent Residue?

With our years of production experience, we can tell you that there are three common ways:

- Wet cloth wipe method: Wipe the surface of polyurethane foam products with a wet cloth to remove residual release agents. This method is suitable for cases where the residual amount is small.

- Solvent cleaning method: Clean the surface of polyurethane foam products with a specific solvent to remove the residual release agent. This method is suitable for cases where the residual amount is large or difficult to remove.

- Hot air drying method: Put the polyurethane foam products into the oven and dry them with hot air to remove the residual release agent. This method is suitable for products with high-temperature tolerance.

It should be noted that when dealing with the release agent residue, you need to choose the appropriate method and pay attention to protecting the surface of the polyurethane foam product to avoid secondary damage to the product. At the same time, it is necessary to control the amount used when using the release agent to avoid excessive residue.

How to Choose the Right Release Agent to Get the Best PU Foam Product Quality?

Choosing the right release agent is the key to obtaining the best quality polyurethane foam products. The following are some considerations for selecting a release agent:

- Consider the type and requirements of polyurethane foam products: Different types of polyurethane foam products have different requirements, such as hardness, viscosity, and surface smoothness. It is necessary to choose the appropriate release agent according to the product requirements.

- Consider the composition and nature of the release agent: Different components of the release agent have different effects on polyurethane foam products, such as the effect on hardness, viscosity, and so on. It is necessary to choose the release agent that meets the requirements of the product.

- Consider the use method and dose of release agent: The different use methods and doses will also affect the product quality, so you need to choose the appropriate use method and dose according to the specific situation.

- Consider the price and environmental friendliness of the release agent: Price and environmental friendliness are also important factors in choosing the release agent. It is necessary to choose reasonably priced and environmentally friendly mold release agents under the premise of meeting the product requirements.

It should be noted that the above factors need to be taken into consideration when selecting the release agent and tested and adjusted in practice in order to obtain the best quality polyurethane foam products.

Conclusão

This article mainly talks about the classification of commonly used release agents and their impact on polyurethane products. As a manufacturer specializing in the production of polyurethane products, the above is a summary of some experiences, and we hope it can be helpful to you. In our next article, we’ll cover 10 commonly used mold-release agents. If you are interested in our products or need to customize and wholesale, you can contact us at any time.