Polyurethane(PU) foam is an important material widely used in construction, automobile, furniture, and other fields. It has a variety of excellent properties such as lightweight, sound insulation, heat preservation, fire resistance, and so on., and is therefore highly favored by various industries. Depending on the application scenario and chemical structure, it can be divided into various types such as rigid polyurethane foam, flexible polyurethane foam, and semi-rigid polyurethane foam, each with different characteristics and application areas. This article will introduce in detail the classification of polyurethane foams and their applications in construction, automotive, furniture, and other applications.

Overview of Polyurethane Foam

Polyurethane foam is a kind of polymer material with a hollow bubble structure, which has many excellent properties such as lightweight, sound insulation, heat preservation, and fire resistance. Its basic structure is a bubble structure formed by a polymer produced by the reaction of isocyanate and polyol, catalyzed by a bubbling agent. Polyurethane foam can be divided into rigid polyurethane foam, elastic polyurethane foam, and semi-rigid polyurethane foam.

The process of polyurethane foam production is briefly described in the following steps:

- First, isocyanate and polyol are mixed and reacted under certain temperature conditions to produce a prepolymer.

- Then, bubbling agents are added to produce bubbles under certain heating conditions.

- Finally, after a certain curing time, the polyurethane foam material is formed.

Polyurethane foam has the following characteristics:

- Lightweight: light density, which can reduce the structural load.

- Sound insulation: good sound absorption performance, which can effectively reduce noise.

- Thermal insulation: excellent thermal insulation performance, which can reduce heat loss.

In general, polyurethane foam is a very important material, widely used in construction, automotive, aviation, furniture, and other fields.

Chemical Structure

The main components of polyurethane foam are isocyanate and polyol. Isocyanate is an organic compound containing NCO groups, which usually reacts with polyols to form polymers. Polyol, on the other hand, is an organic compound with multiple hydroxyl groups (-OH groups), which can be attacked by the NCO groups in isocyanate on reaction to form a closed ring structure. When the two react, the NCO group will form a urea bond (NHCONH) or an acyl-urea bond (RCO-NH-) with the OH group, i.e. a polyurethane structure.

The chemical reaction of polyurethane foam is based on the reaction of isocyanate and polyol and is divided into the following steps:

- Getting prepolymer: Isocyanate prepolymer can be obtained by mixing and reacting with polyol.

- Foaming reaction: Add a foaming agent to the prepolymer to produce CO2 gas, and the polymer will physically bulge under the action of the gas to form various hole structures, while the solution in the mixed material becomes foam material.

- Curing: The surface of the foam material is heated to accelerate curing after molding.

Polyurethane foams have a chemical structure consisting of a polymer composed of polyol and isocyanate, and a bubble structure formed inside the polymer. The specific molecular structure and mechanism depend on the type of polyurethane foam and the production process.

Classification Method

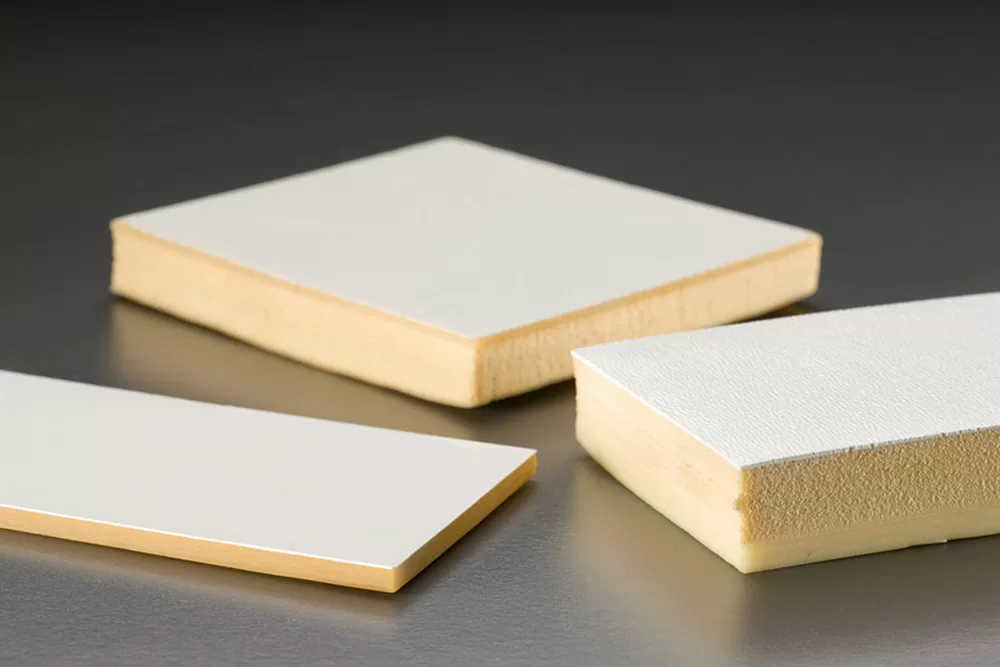

Classification According to Hardness

It can be divided into two categories: hard foam and soft foam. The hardness of rigid foam is relatively high and can be used to produce rigid polyurethane foam products, such as seats, cushions, handles, and so on. The hardness of flexible foam is relatively low, which is used to produce flexible polyurethane foam products, such as cushions, pillows, mattresses, and so on.

Classification According to Density

It can be classified into three categories: high-density polyurethane foam, medium-density polyurethane foam, and low-density polyurethane foam. High-density polyurethane foam has a density of>800 kg/m3, medium-density polyurethane foam has a density of 200-800 kg/m3, and low-density polyurethane foam has a density of <200 kg/m3. Generally, high-density polyurethane foam is suitable for high-load applications, such as car seats, and car tops.; Medium-density polyurethane foam can be used for manufacturing furniture and mattresses; low-density polyurethane foam is suitable for light Low-density polyurethane foam is suitable for light-duty applications, such as packaging materials.

Classification According to Application

According to application, polyurethane foam can be divided into polyurethane foam for construction, polyurethane foam for aerospace, polyurethane foam for transportation, and polyurethane foam for households. For example, polyurethane foam for construction is mainly used for wall insulation, heat preservation, shock absorption, and noise reduction; polyurethane foam for aerospace is used for manufacturing spacecraft, missiles, and satellites; polyurethane foam for transportation is mainly used for car interior decoration, seats; polyurethane foam for a household is used for mattresses, pillows, sofas, cushions, and so on.

Practical example:

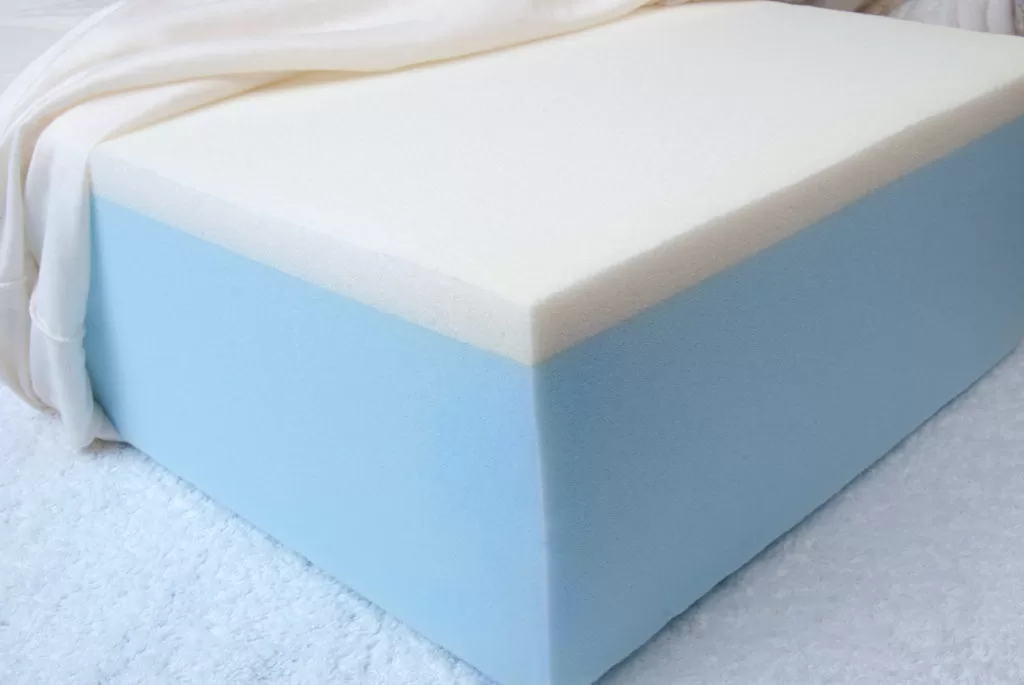

The classification method of hard foam and soft foam can be used in mattress manufacturing. Usually, the hard foam layer of high firmness in mattresses is used to support the body with good support, while the soft foam layer of medium softness is used to relieve the pressure of the body with good comfort.

The density classification method can be used in automobile manufacturing. In terms of body insulation, high-density polyurethane foam is suitable for roof car lift systems and other parts that need high-strength load-bearing; medium-density polyurethane foam is suitable for a variety of parts, such as door panels and floors; low-density polyurethane foam is suitable for lighter-load parts such as headliners and airbags.

The usage classification method can be used for cushion manufacturing. For example, soft foam can be used as a cushion, while hard hard foam can be used for an armrest backrest.

Applications of Rigid Polyurethane Foam

Rigid polyurethane foam is a high-strength, high-rigidity, low-density polymer material often used in construction, aviation, automotive, electronics, furniture, and other fields.

- Construction field: It can be used as insulation, roof and wall partitions, door and window frames, ground covering materials, and so on. Its high strength and durability make it an effective building material that can improve energy efficiency and the stability of building structures.

- Aerospace: It is widely used in bulkheads, seats, frames, and tires in aircraft and spacecraft. Its lightweight and high rigidity can improve the energy saving and flight efficiency of aircraft.

- Automotive field: It is used in automobile seats, padding in doors, aluminum sheets and glass fiber reinforced materials in body structure, and so on. In automotive production, its high strength and durability can reduce weight and enhance safety.

- Electronic field: It can be used for the electronic protective shell, embedded circuit board, cable insulation, and so on. Its excellent electrical insulation performance and stability can ensure the safety and stable operation of electronic equipment.

- Furniture field: It is used as filling material for sofas, chairs, tabletops, and so on. Its lightweight, high strength, moisture-proof, and fire-proof, heat insulation properties make it a kind of furniture material with low cost and high production efficiency.

In conclusion, rigid polyurethane foam is widely used in many fields and can provide excellent properties such as high strength, lightweight, durability, moisture, and fire resistance, and thermal insulation.

Applications of Flexible Polyurethane Foam

Flexible polyurethane foam is a light, soft, and flexible polymer material, which is widely used in furniture, shoe materials, mattresses, car seats, packaging materials, and other fields.

- Furniture field: It can be used as filling material for sofas, chairs, pillows, and so on. Its softness and elasticity performance can ensure a comfortable seating experience and can improve the comfort and beauty of the furniture.

- Shoe material field: It is used in insoles of sports shoes, casual shoes, slippers, and so on. Its high elasticity and abrasion resistance can provide a sense of foot fit and cushioning effect, reducing the pressure and damage to the feet from prolonged use.

- Mattress field: used as filling material in mattress. Its soft performance and breathability can provide a good sleeping experience.

- Car seat field: used as filling material in car seats. Its high elasticity and wear resistance can provide a comfortable seat experience for drivers and passengers and can reduce the feeling of fatigue for a long time.

- Packaging field: used as padding material in product packaging. Its lightweight and elasticity performance can provide good cushioning and protective effects for packaging and ensure the stability and safety of products during transportation.

Flexible polyurethane foam is widely used in many fields and can provide excellent properties such as softness, elasticity, comfort, and so on. It can also be shaped freely and can meet different demand goals.

Application in the Field of Construction

As an excellent insulation material, polyurethane foam has a wide range of applications in the construction field. Its main applications are in building walls, roofs, floors, pipe insulation, sound insulation, and so on. It has the following advantages:

- Good insulating property: It has good insulating properties such as heat insulation, sound insulation, and moisture-proof, which can effectively reduce the loss of energy inside the building.

- Lightweight: With the characteristics of lightweight, it will not add weight pressure to the building, and also reduce the cost of building construction.

- Flame retardant: After special treatment, it has good fire resistance, which can effectively resist the damage of fire to the building.

- Convenient construction: With strong permeability and adhesion, it can adhere well to the building surface and is easy and fast to construct.

The following are some of the disadvantages of polyurethane foam in construction applications:

- Produce harmful gases: Toxic gases such as carbon monoxide, carbon dioxide, cyanide, and so on. will be released when burning. Attention should be paid to fire prevention.

- Easy to be damaged: The surface is easy to be broken or cracked by mechanical damage, ultraviolet radiation, and other factors. High-temperature environments should be avoided.

- Higher cost: Compared with other building insulation materials, the cost of polyurethane foam is higher, which increases the cost of building materials.

When using polyurethane foam, attention needs to be paid to its rational use and treatment so as to give full play to its advantages and avoid its disadvantages from causing adverse effects on the building and human body.

Application in the Field of Transportation

Polyurethane foam is widely used in the field of transportation, and the following is an analysis of its main applications and advantages and disadvantages:

- As heat insulation material: In the field of transportation, it can be used in vehicles or ships as heat insulation material. With its low density and water absorption, polyurethane foam has good heat insulation performance, which can effectively reduce the change of temperature in the vehicle or ship cabin and improve its operational efficiency. In addition, its easy construction and quick installation are one of the reasons why it is widely used in the transportation field.

- As packaging material: it can effectively protect the safety of vehicles, ships, and other large vehicles in the transportation process. Polyurethane foam is lighter in density and tighter in structure, with excellent cushioning and shockproof performance, which can effectively absorb the impact during the collision and reduce the risk of cargo damage.

- As an adhesive and filling material: It can be used as an adhesive or filling material to reinforce or improve components in the transportation field. For example, it can be used to bond various materials (such as metal, fiber, glass, and so on.) and also fill the cavities in vehicles or ships to reduce space waste.

Benefits Analysis

- Good thermal insulation: low density and low water absorption can effectively insulate and reduce energy loss.

- Excellent anti-shock and cushioning performance: It has good flexibility and toughness, which can absorb the vibration and impact of transportation tools very well.

- Convenient construction: With certain fluidity and viscosity, it is easy to spray, inject, and fill during construction.

- Lightweight: It is a relatively light material so the total weight can be reduced during transportation, thus saving energy.

Disadvantage Analysis

- Flammable in open flame: polyurethane foam is flammable and needs fireproof treatment.

- The durability problem: susceptible to yellowing, aging, and hardening by ultraviolet rays, oxidizing gases, and so on.

Application in Furniture Manufacturing

Polyurethane foam has a wide range of applications in furniture manufacturing, mainly in padding, support, sound insulation, shockproofing, and thermal insulation.

- Mattress: It is widely used in mattresses because of its good support and breathability, and it can change according to the shape of the human body so that the human body can get the best rest.

- Sofa: It is used to fill the sofa cushion and backrest cushion to make the sofa more comfortable, stable, and longer life.

- Chairs: It is widely used in chair seat cushions, chair back cushions, and armrest padding to make chairs more comfortable, durable, and with good support.

- Noise reduction: It is used in furniture insulation and soundproofing to reduce sound transmission and improve home quality.

Advantages

- Has good support, and can change according to the body’s form, to ensure that the human body to get the best rest state.

- With good elasticity, can resist long-time use, to ensure a long-time comfort and service life.

- With the advantages of shockproof and heat preservation, can improve the quality of furniture and use effect.

Disadvantages

- Higher manufacturing costs and higher requirements for manufacturers.

- Easily deformed by moisture, which will lead to poor use. So keep it dry and ventilated.

As a furniture material, polyurethane foam can not only improve the comfort and appearance of furniture but also improve the quality and use of furniture, providing consumers with a better home living experience.

Application in the Field of Electronic Appliances

Polyurethane foam is widely used in the field of electronics and electrical appliances, mainly for packaging, protection, and insulation of electronic components.

Advantages

- Polyurethane foam has good sealing, light material, corrosion resistance, easy processing, and good shock absorption ability, which can effectively reduce the damage to electronic components due to vibration and other effects.

- Polyurethane foam has good thermal insulation properties, which can prevent the circuit from malfunctioning due to the high temperature of electronic components.

- Polyurethane foam can also effectively isolate electromagnetic waves to prevent electronic components from interfering with electromagnetic waves and improve the working stability and reliability of electronic components.

Disadvantages

- The low density of polyurethane foam, while protecting electronic components, it is difficult to withstand external forces, easy to break, and difficult to use in the field of electrical appliances that need to withstand high pressure and high strength.

- Some polyurethane foams will age and break under high temperature, humidity, or long-term exposure to ultraviolet light, affecting the service life.

In general, polyurethane foam, as one of the more commonly used materials in the field of electronics and electrical appliances, has a wide range of application prospects and certain limitations and needs to be carefully selected and used according to the actual occasion.

Application in the Field of Environmental Protection

In the field of environmental protection, polyurethane foam is mainly used in the following areas:

- Sound absorption and acoustic insulation Polyurethane foam can effectively absorb and soundproof noise due to its open cell structure, and has excellent sound absorption properties. Therefore, polyurethane foam is widely used for sound insulation and acoustic treatment in sound studios, recording studios, theaters, conference halls, and other places.

- Energy-saving heat insulation Polyurethane foam has excellent heat insulation performance, which can effectively reduce energy consumption and make air conditioning systems more efficient. In construction, cold chain transportation, home appliances, and other fields, polyurethane foam is usually used as an insulation material to achieve energy savings.

- Insulation packaging polyurethane foam can be made into insulation packaging materials, such as refrigerated goods, meal boxes, pharmaceutical insulation packages, and so on. These materials can effectively extend the shelf life of goods and meet the requirements of a green environment.

Advantages

- It has good heat insulation, heat preservation, and sound absorption properties, which can effectively reduce energy consumption and noise pollution.

- It has good processing performance and can be made into different shapes and sizes as needed, which is easy to use and transport.

- The material is light, corrosion-resistant, easy to maintain, and has a long life.

Disadvantages

- The production cost is relatively high, and there may be cost barriers in some use cases.

- Polyurethane foam is fragile, and in some cases, it needs to be equipped with a strong external protective layer to improve its durability and protection.

- Polyurethane foam materials may be damaged when exposed to conditions such as high temperatures and strong acids and bases, and need to be evaluated and protected before use.

Polyurethane foam, as a material commonly used in the environmental protection field, has outstanding advantages but also has some limitations and defects that need attention. In the specific application, it should be carefully evaluated and selected according to its performance characteristics and the needs of the occasion.

Conclusion

Polyurethane foam, with its versatile properties and applications, has become an indispensable material in numerous industries. Its adaptability, ranging from construction to furniture, showcases its significance. However, while it offers numerous benefits, it’s essential to consider its limitations in specific applications. As advancements continue, the potential for polyurethane foam’s broader applications seems promising, making it a focal point for industries aiming for efficiency and innovation.